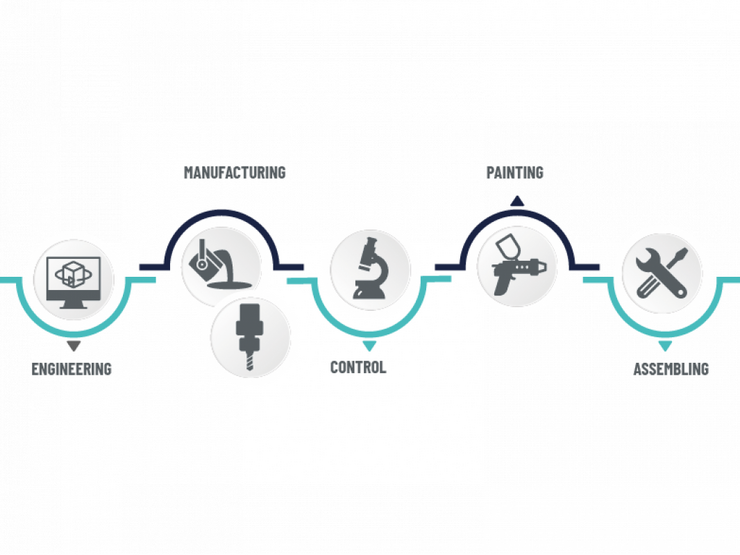

Our Industry solutions

Industrial solutions : from single parts to series production.

LEMER Foundry offers industrial solutions perfectly suited to your fastening, balancing, or thermal safety needs. Together, we define the optimal technical characteristics for your equipment—fuse plugs and cores, sealing leads, pellets, balancing weights, etc.—and handle production, whether for single parts or series, with comprehensive monitoring from design to completion.

Design - Comprehensive support from the project phase onwards.

Our design office works alongside you at every stage : preliminary design, detailed studies, calls for tenders. We analyze your needs to identify the best technical and economic solutions, thereby optimizing your manufacturing costs and implementation times, while guaranteeing impeccable quality.

Choice of tools

We adapt the type of mold to the production volume :

- Sand : small series (less than 5 pieces).

- Concrete : series of 8 to 10 pieces.

- Cast iron : series of 2 to more than 100 pieces.

Mastery of manufacturing processes

Our expertise covers a range of processes, enabling us to provide precise solutions right from the design stage :

- Lead casting in a metalworking shop.

- Insertion of rolled lead into metalwork.

- Machining of raw or rolled lead for integration into metalwork.

- Assembly using lead soldering.

Mechanical integration and complex shielding

Our technical team designs and manufactures double-walled steel/lead shielding, integrating the dimensioning of mechanically welded structures into the design process to provide complete, robust solutions that meet our customers' expectations.

Research & Development

We are constantly on the lookout for new solutions: physical and chemical assembly processes, innovative tools, new products, and lead substitutes. Our goal is to continuously improve our manufacturing methods and strengthen our position with our customers.

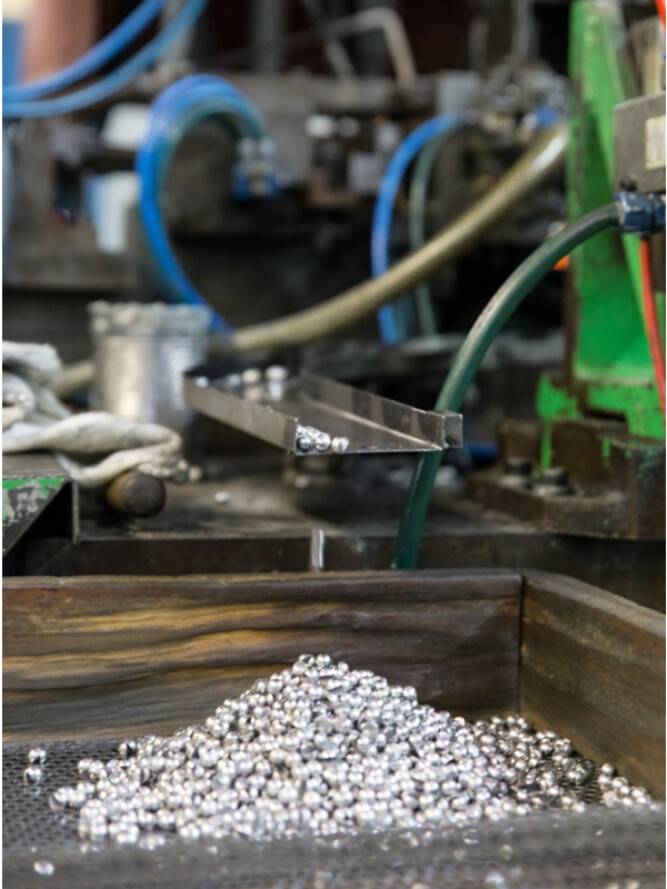

Manufacturing - Capabilities tailored to all your projects.

LEMER Foundry has two production sites in the Nantes region, both certified ICPE (Installations Classées pour la Protection de l’Environnement – Classified Facilities for Environmental Protection).

- Our Carquefou site manufactures parts ranging from a few grams to 200 kg,

- While our Loroux-Bottereau site handles larger parts, from 200 kg to nearly 50 tons.

We produce lead and low-melting-point alloy parts in accordance with standard NF EN 12659, with a stock of the grades most commonly used in the nuclear sector (Pb985R, Pb970R, Pb4Sb) as well as specific low-activity (FA), very low-activity (TFA) and archaeological grades, suitable for the manufacture of shielding for low-background detectors.

Our choice : 100% recycled lead

At LEMER Foundry, we use only recycled lead, mainly from the reprocessing of automotive batteries.

Zero waste, everything is recycled

Machining

We carry out the post-casting machining necessary to obtain precise shapes and specific functionalities (drilling, tapping, etc.). Thanks to our in-house equipment and local partners, we provide partial or complete CNC machining on parts made of lead alloys or other materials (steel, cast iron, stainless steel, aluminum).

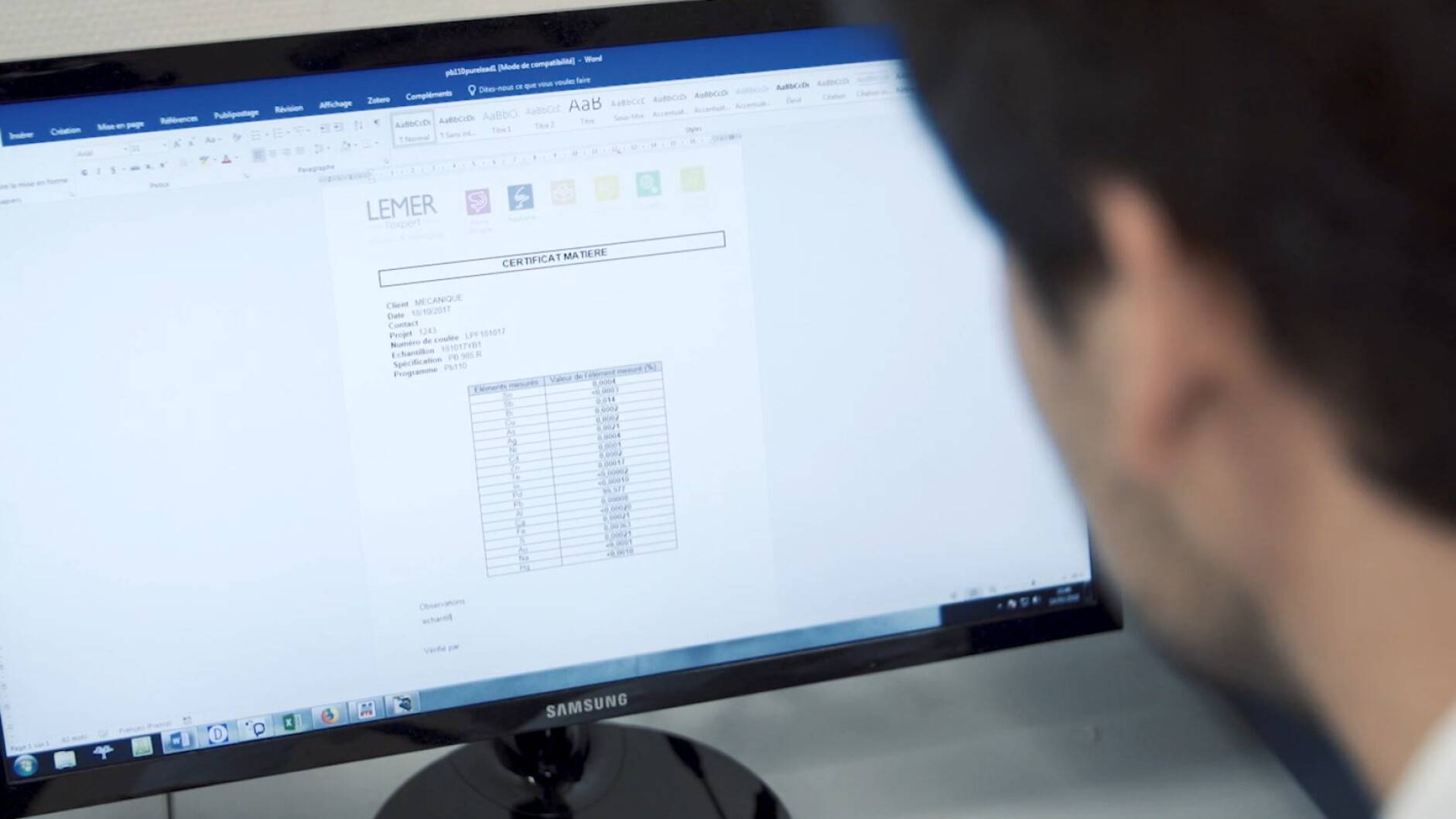

Control & Expertise - Guaranteeing compliance and quality.

Our added value is based on our rigorous control and validation of each project, ensuring that our customers receive products that comply with the most demanding quality standards. We guarantee the compliance of our alloys and services by issuing a Declaration of Conformity in accordance with the NF L 00-015 standard.

All our measuring instruments are regularly monitored, inspected, and certified by an independent body, with periodic inspection documents provided on request.

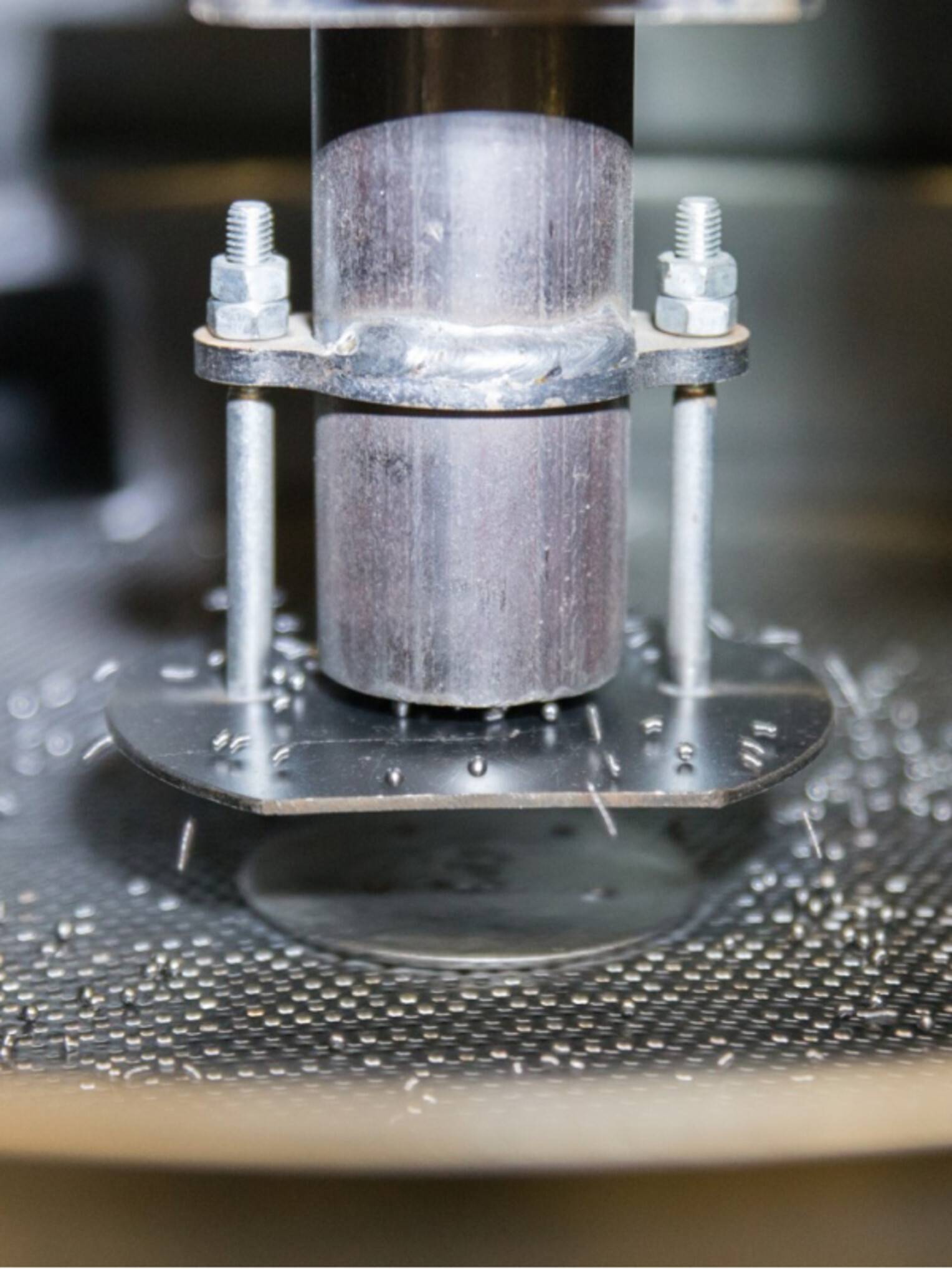

Our laboratory, equipped with state-of-the-art instruments, performs :

- In-depth metallographic analyses.

- Weight checks accurate to one thousandth of a gram.

- Chemical analyses using spectrometry.

- Thermal analyses to verify melting temperature.

- Pull-out tests in accordance with standard NF EN ISO 4624.

- Paint thickness measurements.

- Precise dimensional and geometric checks.

- Additional tests: drop tests, pressure tests, remelting tests, etc.

Painting - Certified expertise for long-lasting protection.

Our ACQPA-certified team will help you choose and apply finishes that guarantee the durability and performance of your mechanically welded parts and structures.

Types of coatings offered

- Epoxy coatings, renowned for their strength and durability.

- Polyurethane paints, offering a robust and attractive finish.

- Decontaminable paints compliant with EDF PID 100/101 standards or equivalent systems, specially adapted to demanding environments.

These coatings are applied to both lead parts and mechanically welded structures, whether provided by our customers or produced as part of a comprehensive service by LEMER Foundry.

Finish levels tailored to your requirements

- Raw parts, simply deburred and carefully sanded.

- Primed parts, for better adhesion of subsequent coats.

- Coated and/or laminated parts.

- Fully painted parts, with a neat and durable finish.

Personalized support

Based on your specifications, plans, or recommendations from our in-house experts, we tailor the finish of your parts.

Assembly - Custom assembly, in the factory or on site.

Factory assembly

LEMER Foundry has high-performance handling equipment, enabling our teams to assemble mechanical sub-assemblies or assemblies of any size.

On-site assembly

For projects requiring specific assembly directly at the customer's site (excluding the nuclear sector), we can put together a team of qualified assemblers. This team operates in France and abroad, with an organization that allows work to start within a maximum of one month.