Fuse core

Innovation and performance for composite parts

Fusible cores are temporary metal inserts cast in low-melting-point alloys. They serve as internal supports for creating high-precision hollow composite parts. Once the composite has hardened, the core melts and is removed, allowing complex internal geometries to be created that would otherwise be impossible to produce. This technology offers lightweight, strong, and dimensionally perfect parts that are ideal for demanding industries.

Why choose LEMER fusible cores ?

With this technology, you get lightweight, high-performance, custom-made composite parts while reducing waste and environmental impact. It is the ideal solution for combining innovation, efficiency, and sustainability in the manufacture of your composite parts.

How does it work ?

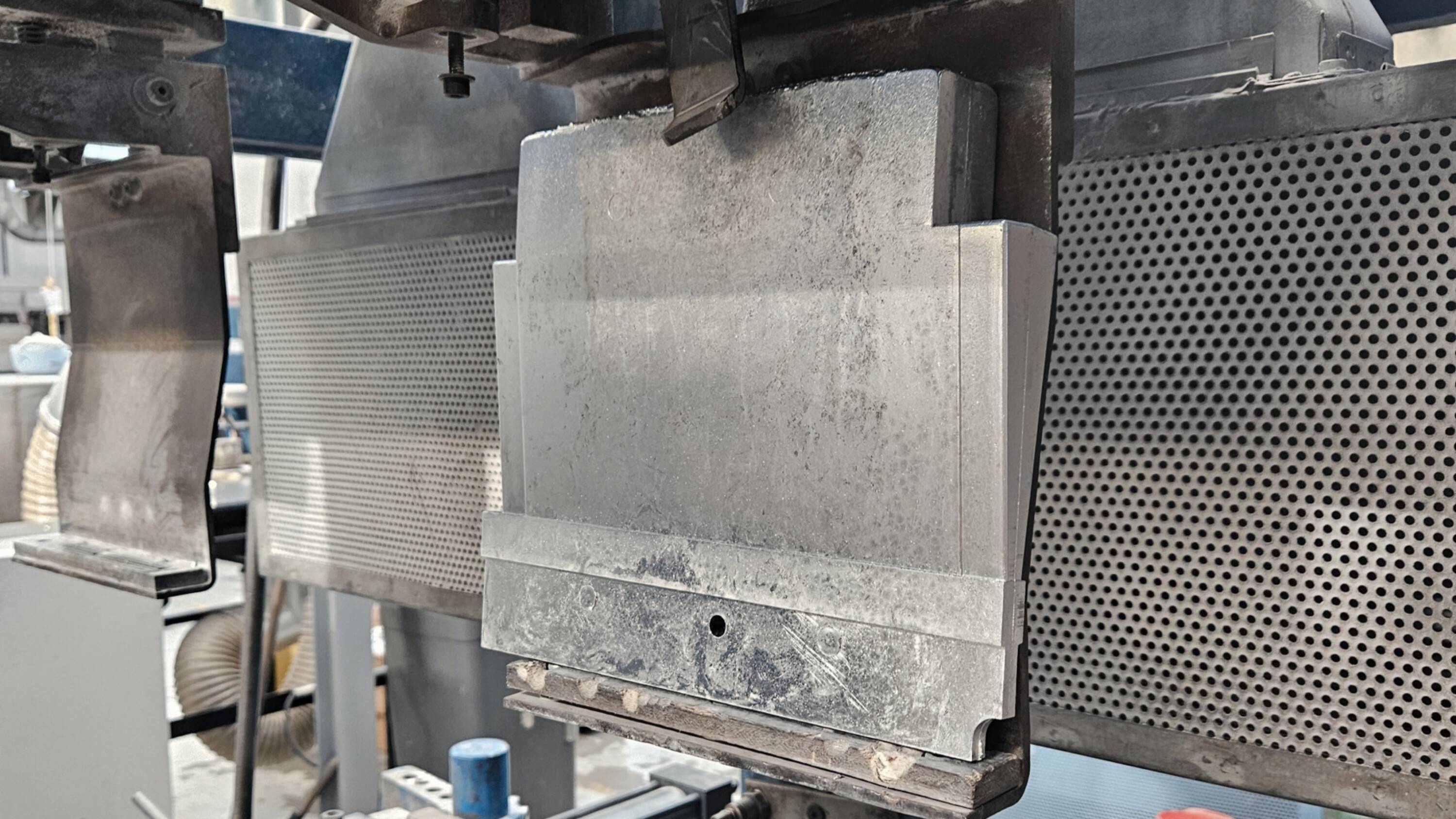

1 Core manufacturing

LEMER Foundry designs cores made of low-melting-point fusible alloys — eutectic, single-phase, binary, or ternary — that are perfectly suited to the vitrification temperature of your composite (from 20°C to 380°C). Each core is precisely controlled using our DSC (Differential Scanning Calorimetry) thermal analyzers, guaranteeing an accurate and reliable melting point for a safe and efficient process.

2 Composite coating

The core is then coated using state-of-the-art processes : filament winding, RTM, and other composite forming techniques.

3 Thermal cycle

During firing, the composite vitrifies and hardens, while the metal core melts without altering the part, creating a perfectly precise hollow internal structure.

4 Extraction and recycling

The molten alloy is recovered, checked, and recycled to make new cores, ensuring a sustainable and environmentally friendly process.

Areas of application

- Aeronautics,

- Aerospace,

- Automotive,

- Competitive sports...

and all sectors requiring lightweight, precise, and durable parts.

The advantages of fusible cores

- Lightweight structures : hollow parts to reduce mass.

- High strength : internal geometry optimized for mechanical performance.

- Highly precise tolerances : superior dimensional control compared to conventional methods.

- Design freedom : complex internal shapes can be achieved.

- Clean and 100% recyclable processes : waste reduction and resource conservation.

Lead : an economical and sustainable solution

Lead offers zero material loss and low energy consumption. This infinitely recyclable metal melts at low temperatures, is easy to dispose of, and requires minimal resources to handle. It is therefore a practical, effective, and 100% recyclable solution for manufacturing fuse elements, while reducing costs and environmental impact.